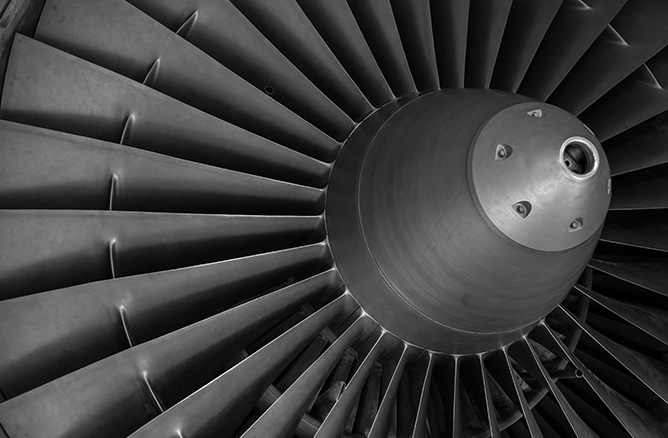

Modern commercial aircraft would not be viable without the jet engine to achieve the necessary altitude and speed. To extract the highest efficiency from a turbofan (pictured), the high pressure turbine design must be tuned to aerodynamic, heat transfer and structural challenges. In particular, the surface of the inlet guide vane is exposed to gas temperatures beyond the metal’s material limits. Surface cooling design is required to maintain part life. This draws a portion of the relatively cool air from the high pressure compressor and routes it around the combustor such that it can be channeled through passages within the turbine’s metal parts and keep them cooler. Once it has completed its journey through the part, the cooling air exits through surface holes to bathe the part’s surface in a film of relatively cool air, insulating the surface from direct contact by the hot gas flow. The cooling air is a negative on the performance of the engine. However it is worthwhile as it allows a high combustion temperature and extends part life at the same time.

The problem is that the high pressure turbine environment is a severe place to live for a metal part and slight variations or ‘off-design’ conditions can either drastically hurt engine performance or greatly shorten the part life. This matters because it leads to more frequent (and costly) engine overhauls or worse, a catastrophic failure. To handle these uncertainties, it is common practice to over-design the part and afterward subject it to multi-dimensional Monte-Carlo variations in conditions to see if failure occurs. This is all done on a computer prior to manufacturing the part.

The Turbine Wall Cooling project was initiated to provide better design tools. The part would then be designed with the uncertainties built-in using duals arithmetic rather than tested after the fact. This would lead to better design trade-off decisions and lower over-design. Part of this project is to design the part with and without the uncertainty. The designs could then be tested with the Monte-Carlo approach to see if the advantages have already been awarded.

This project is enabled by a generic surface cooling model that includes the cooling technologies of backside surface convection, through-metal passage convection, hot-gas side film cooling, base metal capability and thermal barrier coating. These can be traded-off and the generic surface model applied to patches of a turbine part’s surface. This would provide an overall assessment of cooling flow demand and the surface temperatures of the part, both with uncertainties reported. Then the design is judged not only on the required cooling flow and metal temperature but also on the uncertainty. It is not effective to have a low temperature part if the uncertainty is very high.